Lionel MURAT

Lionel est co-fondateur de CIKLab. Ancien responsable de contrôle qualité, il est spécialisé dans la sous-traitance des analyses alimentaires.

“If you can’t measure it, you can’t improve it.”

Quality control is a process that aims to verify with tangible evidence that the quality of a product meets regulatory, internal, and customer requirements.

It also allows for measuring the effectiveness of the production organization: is it deteriorating, maintaining, or improving? Quality control relies, by definition, on checks, tests, or analyses. The main goal is to prevent defective products from ending up with customers or, worse, with consumers.

To measure and improve its effectiveness, the quality control department must have :

To understand the need and necessity of having and tracking indicators, the example of a car trip is very illustrative:

Imagine for a moment that you have to drive from Lille to Marseille with your family. Now picture yourself at the wheel and try to visualize a completely empty dashboard with no indications!

You will quickly start asking yourself some pertinent questions about driving.

There are a multitude of different indicators and not all will be suitable. It is based on the organization of your structure that you will determine the indicators to manage your control activity.

Therefore, it is crucial to have tracking indicators to collect reliable data in real time. These will then allow you to construct performance or efficiency indicators (KPIs)

To manage the activity, as we have seen, it is necessary to have reliable real-time data.

These data are tracking indicators, a snapshot of the activity. They already provide initial answers regarding the management of controls and their organization

💡 Tracking indicators generally serve as the basis for the development of Key Performance Indicators (KPIs).

KPIs are measurable values that allow for the evaluation of an improvement or deterioration of your process in relation to the objectives to be achieved. When applied to quality control, KPIs reflect the performance of your control process.

The method for choosing good performance indicators is actually quite simple.

What is the purpose of my quality control process ? What is the output ?

💡 The output : these are products that have been checked and comply with the expected specifications (technical, legal, regulatory, and commercial).

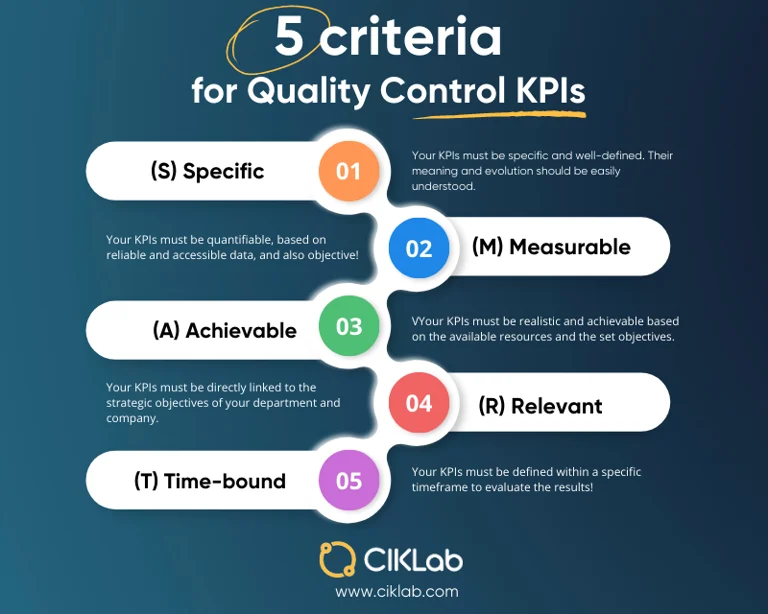

The “S.M.A.R.T” method is a useful mnemonic to use when defining the criteria for choosing KPIs :

For a quality control department, being efficient primarily means the ability to detect non-conformities with certainty. Detect them quickly and as far upstream as possible from the sale of a product. This means controlling the materials that enter the company, those that are in the process of being manufactured, and those that will be offered for sale. But, as is often the case, doing so with a limited budget and tight deadlines.

Let’s take an example:

For a given product and from one year to the next, let’s assume you have the same observation :

Have you been efficient from one year to the next? From a control point of view : yes, because no non-compliant batch has been detected and therefore released.

💡 However, two performance levers can be implemented :

It’s clear that beyond the tracking indicators which can be good, you have the opportunity to set performance or efficiency objectives to be better!

Regardless of the KPIs you use, choose those for which you have the ability to intervene; you won’t improve the quality level of a supplier if no corrective action is imposed by the control department or the purchasing department!

Similarly, for them to be effective, the number of KPIs to track should be limited. Your KPIs are relevant at a given moment, based on your objectives. If the issues are resolved, if the objectives change, don’t hesitate to change your KPIs.

💡Your KPIs should enable you to improve, thus generating actions within your department or your company.

The importance of tracking indicators and Key Performance Indicators (KPIs) in food quality control is crucial. However, collecting reliable data to build your KPIs can be a challenge without the right tools

🚨 When all control data, analysis results, deadlines, and costs are spread across multiple Excel files, it poses a risk :

CIKLab is an innovative solution designed to help food companies efficiently manage control analyses. It allows you to access real-time, reliable, up-to-date, and secure data to build your KPIs!

💡 Easily access all your control data with CIKLab :

Lionel est co-fondateur de CIKLab. Ancien responsable de contrôle qualité, il est spécialisé dans la sous-traitance des analyses alimentaires.

Koalyz SAS

107, allée François Mitterrand

76100 ROUEN – France